उत्पाद विवरण

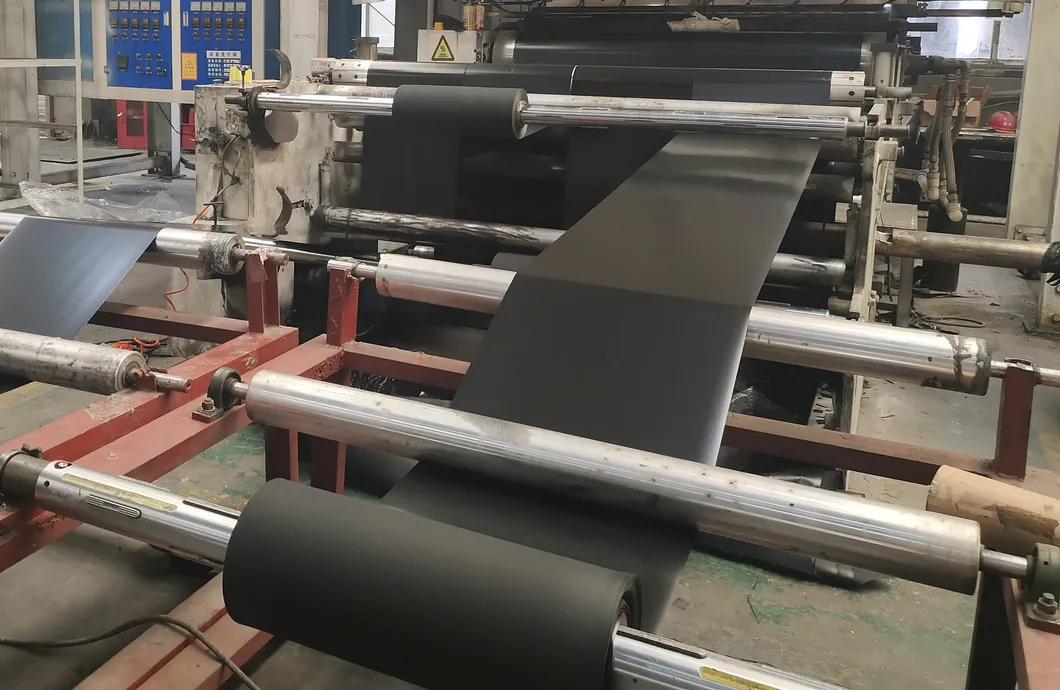

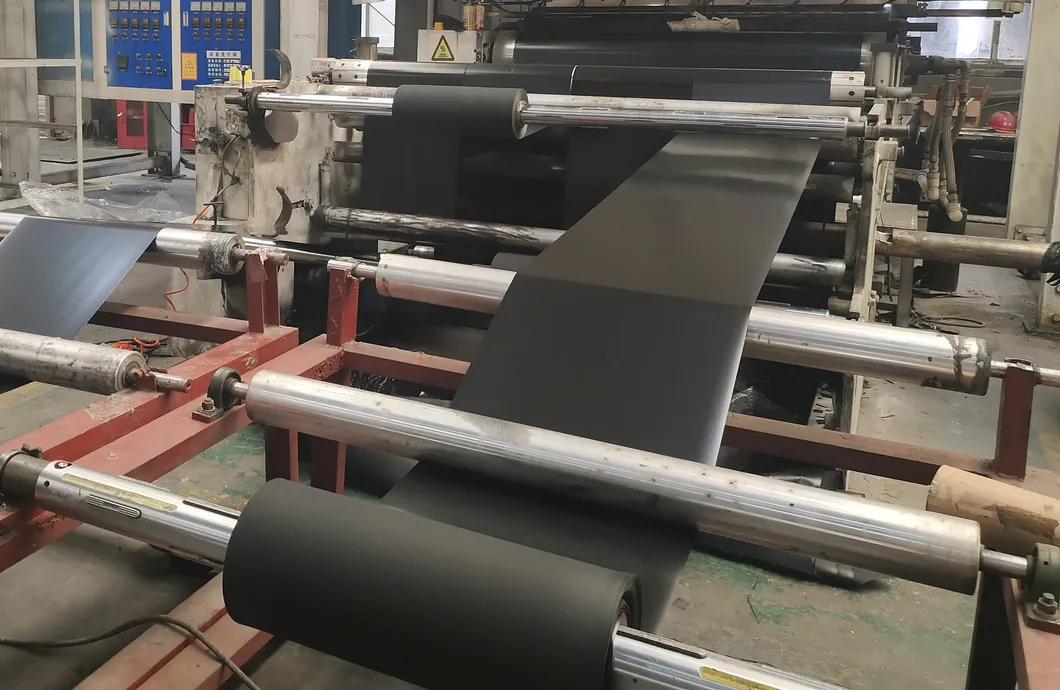

कोल्ड-एप्लाइड एंटीकोरोशन टेप उत्पादन मशीन विशेष रूप से प्रीमियम-गुणवत्ता वाले पॉलीइथिलीन (पीई) सुरक्षात्मक टेप के निर्माण के लिए बनाई गई है, जिसका व्यापक रूप से तेल, गैस, पेट्रोकेमिकल और अपशिष्ट जल उपचार जैसे क्षेत्रों में भूमिगत और जमीन के ऊपर पाइपलाइनों पर जंग को रोकने के लिए उपयोग किया जाता है। ये टेप जंग, नमी और पर्यावरणीय प्रभाव के खिलाफ एक महत्वपूर्ण बाधा के रूप में काम करते हैं, जो पाइपलाइनों की दीर्घकालिक स्थायित्व और प्रदर्शन सुनिश्चित करते हैं।

उत्पादन लाइन से बनी हैतीन मुख्य खंड:

1. पीई बेस फिल्म एक्सट्रूज़न लाइन

2. चिपकने वाला कोटिंग यूनिट

3. स्लिटिंग मशीन

बेहतर दक्षता और विश्वसनीयता के लिए इंजीनियर, यह उपकरण कोल्ड-एप्लाइड एंटीकोरोशन टेप के उत्पादन के लिए एक लागत प्रभावी और मजबूत समाधान प्रदान करता है। इसका पूरी तरह से स्वचालित संचालन श्रम इनपुट को कम करता है जबकि असाधारण स्थिरता और गुणवत्ता बनाए रखता है। मशीन विशेष रूप से उन उद्योगों में अनुप्रयोगों के लिए उपयुक्त है जहां पाइपलाइन सुरक्षा और जंग प्रतिरोध महत्वपूर्ण महत्व के हैं।

तकनीकी प्रक्रियाएं

कोल्ड-एप्लाइड टेप की उत्पादन प्रक्रिया में आमतौर पर निम्नलिखित मुख्य चरण शामिल होते हैं:

-

बेस फिल्म एक्सट्रूज़न

-

कच्चे माल की तैयारी: पॉलीइथिलीन (पीई) को बेस फिल्म कच्चे माल के रूप में तैयार किया जाता है।

-

एक्सट्रूज़न मोल्डिंग: कच्चे माल को एक एक्सट्रूडर में गर्म किया जाता है और पिघलाया जाता है, फिर एक डाई के माध्यम से एक निरंतर बेस फिल्म बनाने के लिए ढाला जाता है।

-

शीतलन और आकार देना: एक्सट्रूडेड बेस फिल्म को समान मोटाई और स्थिरता सुनिश्चित करने के लिए कूलिंग रोलर्स का उपयोग करके ठंडा और आकार दिया जाता है।

-

चिपकने वाला कोटिंग

-

चिपकने वाला तैयार करना: उचित चिपचिपाहट और स्थिरता सुनिश्चित करने के लिए ब्यूटाइल रबर तैयार किए जाते हैं।

-

कोटिंग प्रक्रिया: चिपकने वाला एक चिपकने वाली परत बनाने के लिए कोटिंग उपकरण का उपयोग करके बेस फिल्म के एक या दोनों तरफ समान रूप से लगाया जाता है।

-

स्लिटिंग

-

स्लिटिंग तैयारी: लेपित बेस फिल्म रोल तैयार किया जाता है, और स्लिटिंग उपकरण के मापदंडों को समायोजित किया जाता है।

-

स्लिटिंग ऑपरेशन: चौड़े रोल को स्लिटिंग उपकरण का उपयोग करके आवश्यक चौड़ाई के कोल्ड-एप्लाइड टेप में स्लिट किया जाता है।

-

वाइंडिंग और पैकेजिंग: स्लिट कोल्ड-एप्लाइड टेप को रोल में लपेटा जाता है, पैक किया जाता है, और शिपमेंट के लिए तैयार किया जाता है।

उत्पाद पैरामीटर

उपकरण सूचीपीई बेसिंग फाइल एक्सट्रूज़न लाइन

|

उपकरण का नाम |

मात्रा |

| यूनिट |

वैक्यूम स्वचालित फीडर |

यूनिट |

| यूनिट |

हॉपर ड्रायर |

यूनिट |

| 3 |

SJ-75X30 एक्सट्रूडर |

यूनिट |

| 4 |

हाइड्रोलिक स्क्रीन चेंजर |

यूनिट |

| 5 |

डीआईई हेड मोल्ड टाइप 1000 |

यूनिट |

| 6 |

मल्टी-रोलर टेप-कास्टिंग मशीन |

यूनिट |

| 7 |

वाइंडिंग मशीन |

यूनिट |

| 8 |

पीएलसी कंप्यूटर नियंत्रण प्रणाली |

यूनिट |

चिपकने वाला कोटिंग मशीन

| नहीं। |

उपकरण नाम |

क्वा। |

| यूनिट |

फ्रेम |

यूनिट हमारे फायदे |

| यूनिट |

200N·M चुंबकीय पाउडर ब्रेक + सिलिकॉन स्टिक 1300mm कोरोना प्रोसेसर के साथ |

यूनिट हमारे फायदे |

| 3 |

100N·M चुंबकीय पाउडर ब्रेक |

यूनिट हमारे फायदे |

| 4 |

100N·M चुंबकीय पाउडर क्लच |

यूनिट हमारे फायदे |

| 5 |

200N·M चुंबकीय पाउडर क्लच |

यूनिट हमारे फायदे |

| 6 |

पेंच |

यूनिट हमारे फायदे |

| 7 |

फोर्स-फीड डिवाइस |

यूनिट हमारे फायदे |

| 8 |

स्थिर दबाव प्रणाली |

यूनिट हमारे फायदे |

| 9 |

चिपकने वाला डिलीवरी पाइप |

यूनिट हमारे फायदे |

| 10 |

वाइंडिंग मशीन |

यूनिट हमारे फायदे |

| 11 |

अनवाइंडिंग मशीन2 |

यूनिट हमारे फायदे |

| कोटिंग कंपाउंड उपकरण |

1 |

यूनिट हमारे फायदे |

| मुख्य इंजन आवृत्ति कनवर्टर |

1 |

यूनिट हमारे फायदे |

| एक्सट्रूडर आवृत्ति कनवर्टर |

1 |

यूनिट हमारे फायदे |

| थर्मल स्विच |

1 |

यूनिट हमारे फायदे |

| पीएलसी |

1 |

यूनिट हमारे फायदे |

-उन्नत तकनीक अपनाएं

-स्थिर संचालन

-उच्च डिग्री का स्वचालन, श्रम लागत की बचत

-अच्छी गुणवत्ता, अंतर्राष्ट्रीय मानक को पूरा करती है

-पूर्ण उत्पादन समाधान की आपूर्ति करें: डिजाइन, स्थापना, कमीशनिंग, प्रशिक्षण

-आपको दुनिया भर से 389 सेट उत्पादन अनुभव साझा करें

-9 पेशेवर वरिष्ठ इंजीनियर हैं

-चीन में एक उच्च-अंत प्लास्टिक मशीनरी उपकरण विशेषज्ञ वर्कस्टेशन होना

ग्राहक मामले

कंपनी प्रोफाइल

क़िंगदाओ हुआशिदा

, एक वैश्विक प्लास्टिक एक्सट्रूज़न उपकरण आर एंड डी निर्माता और समाधान प्रदाता, हमारे 70% ग्राहक यूरोप, संयुक्त राज्य अमेरिका, मध्य पूर्व और दक्षिण पूर्व एशिया और अन्य विदेशी देशों से हैं।हुआशिदा की आर एंड डी और विनिर्माण इन्सुलेशन पाइप उत्पादन लाइन का व्यापक रूप से नगरपालिका गर्मी, सीवेज, पानी की आपूर्ति, प्राकृतिक गैस और संचार पाइप नेटवर्क निर्माण, कच्चे तेल पाइपलाइन परिवहन में उपयोग किया जाता है और कृषि सिंचाई। हमारे पर निर्भर नवाचार और उत्पाद शक्ति, हमने 1000 से अधिक निर्माताओं के लिए अनुकूलित तकनीकी सेवाएं प्रदान की हैं, जिनमें 400 से अधिक घरेलू उद्यम और 500 से अधिक विदेशी उद्यम शामिल हैं और ग्राहक चिंताओं को प्रभावी ढंग से हल करने के लिए एक 24 घंटे की वैश्विक सेवा प्रतिक्रिया तंत्र स्थापित किया है। हमारे मुख्य उत्पाद हैं:

1. प्री-इंसुलेटेड पाइप प्रोडक्शन लाइन के लिए एचडीपीई जैकेट पाइप

2. कठोर प्री-इंसुलेटेड पाइप प्रोडक्शन लाइन

3. लचीली प्री-इंसुलेटेड पाइप (पीईआरटी) उत्पादन लाइन

4. स्टील पाइप एफबीई/2एलपीई/3एलपीई एंटी-कोरोशन कोटिंग लाइन

5. स्टील पाइप डेरस्टिंग लाइन

6. पीई

दबाव पाइप/पानी गैस आपूर्ति पाइप उत्पादन लाइन6. पीपी/पीई प्लास्टिक बोर्ड/शीट/जियोमेम्ब्रेन उत्पादन लाइन

7.

एनबीआर पीवीसी टीहर्मल इन्सुलेशन ट्यूब/प्लेट उत्पादन लाइन 8. पाइपलाइन एंटी-कोरोशन सामग्री और उपकरण: हीट सिकुड़न संयुक्त कोटिंग आस्तीन, इलेक्ट्रो-फ्यूजन वेल्डेबल संयुक्त आस्तीन, पोर्टेबल वेल्डिंग गन (एक्सट्रूडर), पीई पीपी वेल्डिंग रॉड।

हम 400 से अधिक विदेशी ग्राहकों के साथ काम कर रहे हैं और अपने उत्पादों को कजाकिस्तान, उज्बेकिस्तान, ईरान, तुर्की, रूस, नाइजीरिया और अन्य देशों में निर्यात कर रहे हैं।

हमारी टीम

डिलीवरी

प्रदर्शनी

प्रमाणन

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!  आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!