पीई विरोधी संक्षारण हीट सिकुड़ने पूर्व अछूता पाइप के लिए सिकुड़ने योग्य आस्तीन

उत्पाद का वर्णन

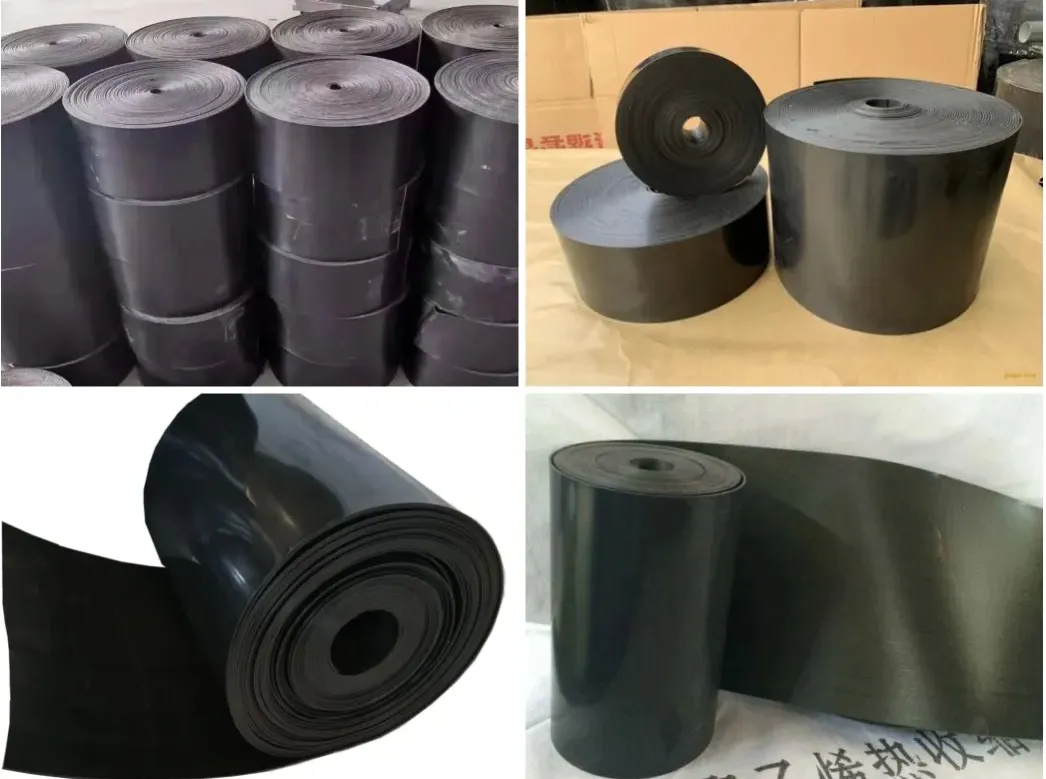

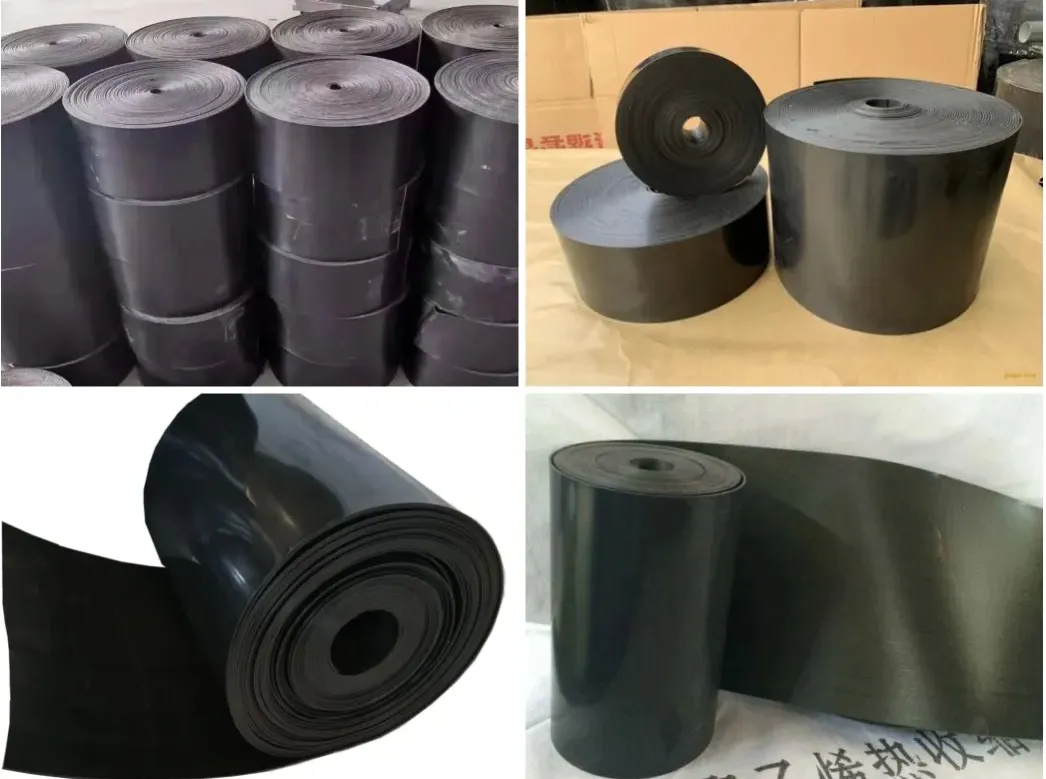

पीई हीट सिकुड़ने योग्य आस्तीन दो परतों की संरचना है, यह विकिरण क्रॉस-लिंक्ड पॉलीएथिलीन समर्थन और विशेष गर्मी पिघलने चिपकने वाला पदार्थ से बना है। स्टील पाइप पर लागू करने के लिए सिकुड़ने वाला आवरण गैर विलायक दो घटक epoxy प्राइमर।

हीट फ्लोट चिपकने वाला पीई समर्थन, इस्पात पाइप और एपॉक्सी प्राइमर के साथ अच्छा बंधन है। पीई वापस सिकुड़ता है, चिपकने वाली परत पिघल जाती है, आस्तीन पाइप जोड़ों के चारों ओर बारीकी से लपेटता है।यह इपॉक्सी प्राइमर के साथ मिलकर एक ठोस और निरंतर एंटी-जंग निकाय बनाता है, जो कारखाने की स्थितियों में 3-परत एंटीकोरोसिव कोटिंग के समान है। यह जंग, पहनने, प्रभाव, यूवी और उम्र बढ़ने के लिए प्रतिरोधी है, संचालित करने में आसान है।

उत्पाद पैरामीटर

उत्पादन लाइन मॉडल

| (मॉडल) |

(चौड़ाई) |

मोटाई ((एमएम) |

गति ((m/min) |

आउटपुटr ((kg/h) |

| एसबीजेजेड-800 |

650 |

0.18-1.5 |

1-25 |

80-320 |

| एसबीजेजेड -1000 |

800 |

0.2-2.0 |

1 से 20 |

150-430 |

| एसबीजेजेजेड -1500 |

1350 |

1-10 |

0.5-10 |

150-450 |

| एसबीजेजेड -2000 |

1850 |

2-15 |

0.5-8 |

300-550 |

| एसबीजेजेड -2200 |

2000 |

1-10 |

0.4-3 |

420-820 |

| एसबीजेजेड-3000 |

2850 |

2-8 |

0.2-3 |

500-1200 |

| एसबीजेजेड-7000 |

6800 |

2-6 |

0.2-2 |

600 से 1560 |

उन्नत प्रौद्योगिकी का अवशोषण, क़िंगदाओ Huashida मशीनरी कं, लिमिटेडस्वतंत्र बौद्धिक संपदा अधिकारों के साथ एक एकीकृत इकाई विकसित की--पीपी/पीई/पीएस/एचआईपीएस/एबी/पीवीसी शीट एकल-परत और बहु-परत सह-विसारित उत्पादन लाइनप्लास्टिक शीट और बोर्ड उत्पादन लाइनों के पहले घरेलू निर्माताओं में से एक के रूप में, क़िंगदाओ हुआशिदा मशीनरी कं, लिमिटेडइसके पास मजबूत तकनीकी फायदे और स्थापना और कमीशन में समृद्ध अनुभव है।हमारी कंपनी द्वारा उत्पादित पीपी/पीई/पीएस/एचआईपीएस/एबी/पीवीसी शीट सिंगल लेयर और मल्टी लेयर को-एक्सट्रूज़न लाइन का प्रदर्शन अंतरराष्ट्रीय उन्नत और घरेलू अग्रणी स्तर पर पहुंच गया है।

-

अनुकूलन:

-

रेखाएं आपके अनुकूल बनाई जा सकती हैं विशिष्ट आउटपुट आवश्यकताएं (चौड़ाई, मोटाई, क्षमता) और कारखाने का लेआउट।

-

के लिए एकीकरण विकल्प स्वचालित स्टैकिंग, पैकेजिंग या इनलाइन गुणवत्ता निरीक्षण

हमारे फायदे

थर्मल सिकुड़ने वाला टेप मुख्य रूप से एक पॉलीएथिलीन आधार सामग्री से बना है जिसे विकिरण-क्रॉसलिंक किया गया है और हमारी कंपनी के स्वामित्व वाले गर्म पिघलने वाले चिपकने वाले के साथ गर्म-लैमिनेट किया गया है।

हीट-क्रशिंग रैपिंग टेप श्रृंखला को दफन और भूमि के ऊपर स्टील पाइपलाइनों और इन्सुलेशन बाहरी परतों की संक्षारण सुरक्षा के लिए डिज़ाइन किया गया है।यह मुख्य रूप से इस्पात पाइप मोड़ के विरोधी जंग लपेटन के लिए प्रयोग किया जाता है, पाइपलाइन कोटिंग की मरम्मत, और 3 पीई कोटिंग रैपिंग।

स्थापना के निर्देश

01 स्थापना का पहला चरण

इस्पात पाइप की सतह को पीसें और साफ करें। वेल्ड जॉइंट को अच्छी तरह से साफ करें। वेल्ड स्लग, स्प्रे, और परिधि वेल्ड और उसके आसपास के सभी बम्पर को हटा दें।

अगर किसी कोटिंग के किनारे पर छील, जंग या दरारें दिख रही हैं, तो उसे साफ करें।

ओवरलैपिंग परतों के साथ संयुक्त क्रॉस-प्रेस बंधन शुरू करें.

02 स्थापना का दूसरा चरण

लगभग के लिए इस्पात पाइप प्रीहीट करने के लिए एक गैस टॉर्च का उपयोग करें5°C, नमी और अशुद्धियों को दूर करता है।

प्राइमर तैयार करें और इसे समान रूप से लागू करें। प्राइमर एक त्वरित सूखने वाला प्रकार होना चाहिए जो बाद में कोटिंग के लिए उपयुक्त हो।

03 संयुक्त क्रॉस-प्रेस बंधन और ओवरलैपिंग

क्रॉस-प्रेस बंधन और ओवरलैपिंग प्रक्रिया शुरू करें।

सिकुड़ने वाले टेप को गर्म करते समय लौ की तीव्रता को नियंत्रित करें और धीरे-धीरे गर्म करें। टेप के किसी भी बिंदु को बहुत लंबे समय तक लौ के संपर्क में न लाएं। पूरी सतह पर समान ताप सुनिश्चित करें।

चिपकने वाले टेप को कसने और चिपकने वाले पदार्थ के बहने के लिए जांचें। यदि किसी क्षेत्र में पर्याप्त चिपकने वाले पदार्थ का प्रवाह नहीं दिखता है, तो चिपकने वाले पदार्थ को दिखाई देने तक फिर से गर्म करने के लिए टॉर्च का उपयोग करें।पाइप के निचले हिस्से पर विशेष ध्यान दें और उचित चिपकने वाला प्रवाह सुनिश्चित करें.

04 हवा के बुलबुले हटाने के लिए पीटीएफई रोलर का प्रयोग करें

हवा के बुलबुले को दबाने और खत्म करने के लिए पॉलीटेट्राफ्लोरोएथिलीन (पीटीएफई) रोलर का प्रयोग करें, जिससे एक चिकनी और पूरी तरह से बंधे हुए सतह सुनिश्चित हो।

क़िंगदाओ हुआशिदा - उन्नत प्लास्टिक एक्सट्रूज़न समाधानों में आपका वैश्विक भागीदार।

आज ही उद्धरण या तकनीकी विनिर्देश मांगें!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!  आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!